Fast Deployment of Smart Manufacturing

It is difficult for small to midsize companies to find a suitable solution to quickly upgrade to smart manufacturing

Challenges Factories are Facing

Shortage of Manpower and Rising Wages

Demand of Shorter Product Delivery Circle

Varies of Market Demand

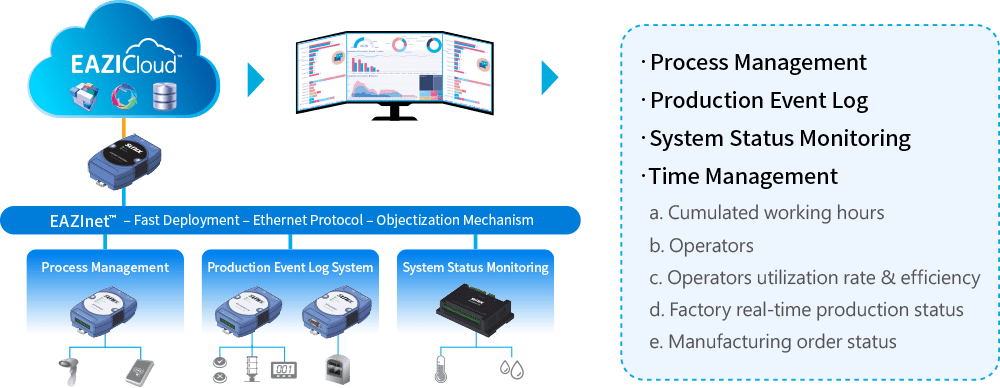

SUNIX Information Management System

Rethink from IT Point of View(IT/OT/CT)

• No modification needed, easy to build

• Able to obtain updated field data directly

• Fast deployment (~3 months)

• Allow easy change of processes, by adapting to small number of different orders

Factory Facility Informatization

• Meeting the needs of different management levels

• Avoids human errors with production informatization

• Instant notification from factory production status

Cost Flexibility for Customize Requirements

• High flexibility on project and cost management

• Break through from traditional project complexity and higher cost

• Project personalization adjusted to customer requirements

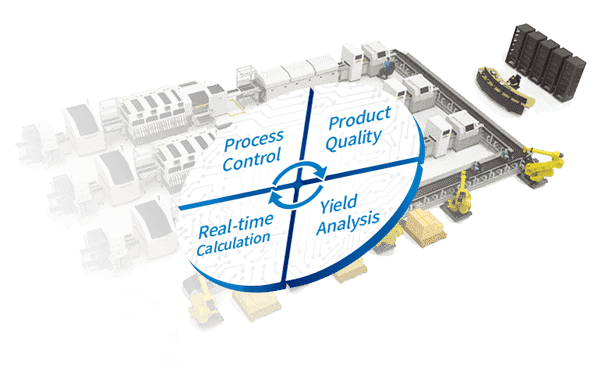

Informatization Architecture

Truly Meeting Manufacturers Requirement

Instant

Stable and reliable data transmission

Able to find out problem promptly to avoid huge loses

Trusted

Non manual processing or human data entry

Reducing the misjudgement from decision makers

Practical

Accurate job time management and scheduling

Improve production efficiency and reducing personnel cost

Speedy

Flexibility on production line process

Increase yield rate, effectively reducing cost

Importing the benefits of production line informatization

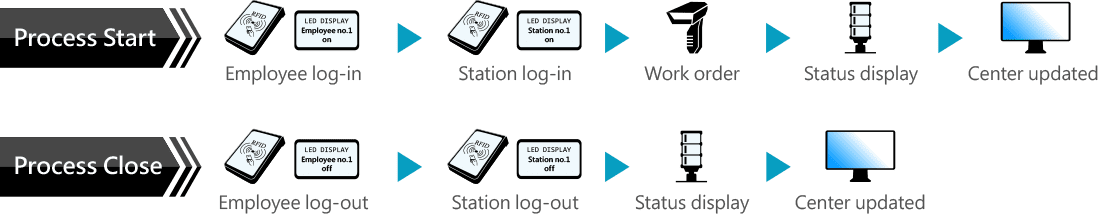

Employee Time Management

Productivity Calculation

Efficiency Analysis

Real-time Status

Schedule Estimation

Staffing

Quality Control

Successful Story

LED production line information management system

Central control

• Real-time production line status

• Machine operators and hours accumulation

• Statistical and analytical reports

• Number of workers

• Event log